Sep 13 2023

Sep 13 2023

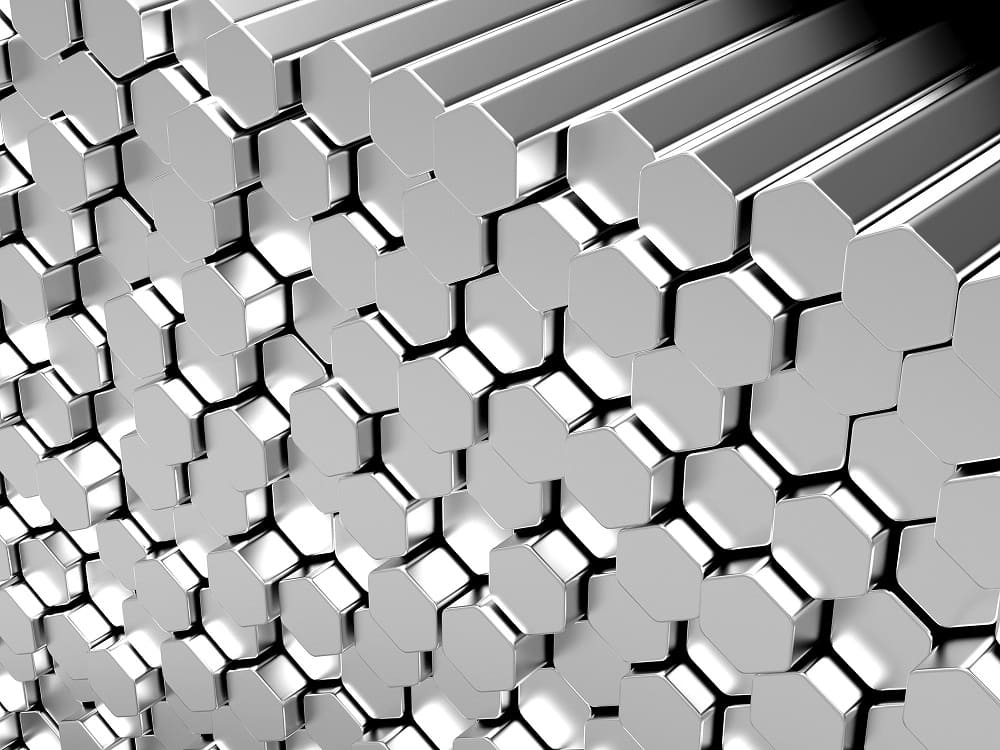

Are you in the market for a stainless steel hexagonal rod? Look no further! Whether you're a seasoned professional or just starting out, choosing the right stainless steel hexagonal rod can make all the difference in your projects. From its durability to its versatility, this remarkable piece of metal offers a wide range of benefits that are sure to elevate your work to new heights. In this ultimate guide, we'll take you through everything you need to know about selecting the perfect stainless steel hexagonal rod for your needs. So grab your safety goggles and let's dive into the world of Aofeng Metal Material and find out why their stainless steel hexagonal rods are truly top-notch!

Stainless steel hexagonal rods offer a wide range of benefits that make them an excellent choice for various applications.

First and foremost, stainless steel is known for its exceptional strength and durability. This means that hexagonal rods made from stainless steel are able to withstand heavy loads and resist deformation, making them ideal for structural or load-bearing purposes.

In addition to their strength, stainless steel hexagonal rods also exhibit excellent corrosion resistance. This makes them highly resistant to rust and staining, even in harsh environments such as marine or industrial settings.

Furthermore, stainless steel is a low-maintenance material that requires minimal care. It does not need regular painting or coating to protect against corrosion, saving both time and money in the long run.

Another advantage of using stainless steel hexagonal rods is their aesthetic appeal. The smooth surface finish of these rods gives them a sleek and polished look, which can enhance the overall appearance of any project they are used in.

Stainless steel is environmentally friendly as it is 100% recyclable. Choosing stainless steel hexagonal rods promotes sustainability by reducing the demand for new raw materials.

The benefits of using stainless steel hexagonal rods make them a versatile and reliable choice for a wide range of applications in various industries. Whether you need strong support structures or corrosion-resistant components, these rods have got you covered!

When it comes to choosing the right stainless steel hexagonal rod, there are several important factors that need to be taken into consideration. First and foremost is the grade of stainless steel. Different grades offer varying levels of corrosion resistance, strength, and durability.

Size and dimensions are also crucial considerations. The diameter and length of the rod should align with your specific requirements for your project or application. It's essential to ensure that you have accurate measurements in order to choose a rod that will fit perfectly.

Another factor to keep in mind is the surface finish of the hexagonal rod. Depending on your intended use, you may prefer a polished or brushed finish for aesthetic purposes or a more textured finish for enhanced grip.

Corrosion resistance is another key factor when selecting a stainless steel hexagonal rod. Ensure that you choose a grade with high corrosion resistance if it will be exposed to harsh environments or chemicals.

By carefully considering these factors - grade, size and dimensions, surface finish, and corrosion resistance - you can confidently select the right stainless steel hexagonal rod for your specific needs and applications!

When it comes to choosing the right stainless steel hexagonal rod, one of the most important factors to consider is the grade of stainless steel. Stainless steel is available in different grades, each with its own unique properties and characteristics.

One commonly used grade for stainless steel hexagonal rods is 304. This grade offers excellent corrosion resistance and good strength, making it suitable for a wide range of applications. Another popular grade is 316, which has even higher corrosion resistance and added molybdenum for increased durability in harsh environments.

Other grades such as 410 and 420 are known for their high hardness and wear resistance, making them ideal for applications that require cutting or machining. On the other hand, duplex grades like 2205 offer a combination of strength and corrosion resistance, making them suitable for marine environments.

It's important to carefully assess your specific needs before selecting a grade of stainless steel hexagonal rod. Consider factors such as environmental conditions, desired mechanical properties, and budget constraints to determine the best choice for your project. Consulting with an expert can also help ensure you select the right grade for your application.

Remember that choosing the correct grade will ultimately determine the performance and longevity of your stainless steel hexagonal rod!

When it comes to choosing the right stainless steel hexagonal rod, size and dimensions play a crucial role. The size of the rod will determine its strength and stability in various applications.

Consider the diameter of the hexagonal rod. This is an important factor as it determines how much weight or pressure it can withstand without bending or breaking. A thicker diameter will generally offer more durability, making it suitable for heavy-duty applications.

Next, consider the length of the rod. Depending on your specific needs, you may require a longer or shorter rod. Longer rods are ideal for projects that require extended reach or multiple connections. On the other hand, shorter rods are more manageable and easier to work with in tight spaces.

Additionally, pay attention to the overall dimensions of the hexagonal rod. Ensure that it fits seamlessly into your project without any modifications needed.

Remember that selecting the right size and dimensions for your stainless steel hexagonal rod is essential for optimal performance and longevity. Take into account factors such as load-bearing requirements and available space when making your decision.

When choosing the right stainless steel hexagonal rod, one important factor to consider is the surface finish. The surface finish of a stainless steel hexagonal rod can greatly impact its appearance and performance in various applications.

The surface finish refers to the texture and smoothness of the metal's outer layer. It plays a critical role in determining how well the rod resists corrosion, withstands wear and tear, and looks aesthetically pleasing. There are different types of surface finishes available, each offering unique benefits.

One common type of surface finish for stainless steel hexagonal rods is a bright or mirror finish. This type of finish provides a smooth and reflective appearance, making it ideal for decorative purposes or when visual appeal is important. It also offers excellent corrosion resistance and ease of cleaning.

Another option is a brushed or satin finish, which creates a textured look with fine parallel lines on the metal's surface. This type of finish helps to hide scratches and fingerprints while providing good corrosion resistance. It is commonly used in architectural applications where both durability and aesthetics are essential.

For more heavy-duty applications requiring extra protection against harsh environments or frequent handling, you may opt for a bead blasted or matte finish. This rougher texture enhances grip while maintaining acceptable levels of corrosion resistance.

The choice of surface finish depends on your specific needs and preferences for functionality as well as aesthetics. Considering factors such as desired appearance, level of corrosion resistance required, and intended application will help you select the right stainless steel hexagonal rod with an appropriate surface finish

Corrosion resistance is a critical factor to consider when choosing the right stainless steel hexagonal rod. This property determines the rod's ability to withstand various environmental conditions and chemical exposure without deteriorating or rusting.

One of the main reasons why stainless steel hexagonal rods are preferred over other materials is their exceptional corrosion resistance. Stainless steel contains chromium, which forms a protective oxide layer on the surface, preventing corrosion from occurring. The higher the chromium content, the better the corrosion resistance.

Additionally, other alloying elements such as nickel and molybdenum can enhance stainless steel's corrosion resistance properties. These elements contribute to forming a more robust and stable passive film on the surface of the hexagonal rod.

When selecting a stainless steel hexagonal rod for applications in corrosive environments like marine or chemical industries, it is crucial to choose a grade with high corrosion-resistant properties. Grades such as 316 or 304L are commonly used due to their excellent resistance against chloride-induced pitting and crevice corrosion.

Regular maintenance and proper care also play an important role in preserving the corrosion resistance of stainless steel hexagonal rods. Cleaning them regularly using mild detergents and avoiding contact with harsh chemicals will help maintain their integrity over time.

Considering factors like grades containing appropriate alloying elements and practicing regular maintenance will ensure optimal performance from your chosen stainless steel hexagonal rod in corrosive environments

Different types of stainless steel hexagonal rods are available in the market, each with its own unique properties and characteristics. One common type is the 304 grade stainless steel hexagonal rod, which offers excellent corrosion resistance and is suitable for a wide range of applications. Another popular option is the 316 grade stainless steel hexagonal rod, known for its superior strength and ability to withstand harsh environments.

For those requiring even greater durability, there are also duplex stainless steel hexagonal rods available. These rods combine the best qualities of both austenitic and ferritic stainless steels, offering high strength along with enhanced corrosion resistance.

In addition to these standard grades, there are also specialized alloys such as 17-4PH stainless steel hexagonal rods that offer exceptional hardness and heat resistance. These alloys are commonly used in industries such as aerospace and defense where extreme conditions are encountered.

When choosing a specific type of stainless steel hexagonal rod, it's important to consider factors such as the intended application, budget constraints, and desired level of corrosion resistance. Consulting with experts or suppliers can provide valuable insights into selecting the right type based on individual requirements.

Having a variety of options allows users to choose the most suitable stainless steel hexagonal rod that will meet their specific needs and ensure long-lasting performance in various applications.

Stainless steel hexagonal rods are versatile and widely used in various industries due to their unique properties. One of the key applications for these rods is in construction, where they are commonly used for structural support and framing. The hexagonal shape provides added strength and stability, making them ideal for load-bearing applications.

In the automotive industry, stainless steel hexagonal rods find use in manufacturing components such as exhaust systems, suspension parts, and engine mounts. The corrosion resistance of stainless steel ensures durability even under harsh conditions.

Another important application is in the aerospace industry, where these rods are utilized for aircraft construction and maintenance. Their high strength-to-weight ratio makes them suitable for critical components that require both strength and lightweight properties.

The food processing industry also benefits from using stainless steel hexagonal rods due to their sanitary properties. They are commonly used in equipment like conveyor belts, mixers, and tanks that come into contact with food products.

Moreover, these rods have applications in marine environments due to their excellent corrosion resistance against saltwater exposure. They are widely used in boat fittings, shipbuilding structures, and offshore platforms.

Stainless steel hexagonal rods have diverse applications across multiple industries thanks to their durability, strength-to-weight ratio, and corrosion resistance properties.

To ensure the longevity and optimal performance of your stainless steel hexagonal rods, proper maintenance and care are essential. Here are some tips to keep in mind:

1. Regular cleaning: Clean the surface of the rods regularly using mild soap or detergent mixed with warm water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface.

2. Remove stains promptly: If you notice any stains on the rods, it's important to remove them as soon as possible. Use a non-abrasive cleaner specifically designed for stainless steel and follow the manufacturer's instructions.

3. Avoid harsh chemicals: When cleaning or maintaining stainless steel hexagonal rods, avoid using harsh chemicals such as bleach or ammonia-based cleaners, as they can damage the material.

4. Prevent rusting: Stainless steel is known for its corrosion resistance, but it's still important to take preventive measures against rust formation. Keep your hexagonal rods dry and avoid prolonged exposure to moisture or corrosive substances.

5. Protect from scratches: Although stainless steel is durable, it can still be prone to scratching if not handled properly. Avoid dragging heavy objects across the surface of the rods and consider using protective covers when storing or transporting them.

6. Regular inspections: Periodically inspect your stainless steel hexagonal rods for any signs of damage, such as dents, cracks, or loose fittings. Address these issues promptly to prevent further damage.

By following these maintenance guidelines, you can ensure that your stainless steel hexagonal rods remain in excellent condition for years to come!

In conclusion, Choosing the right stainless steel hexagonal rod involves considering factors such as grade selection based on specific requirements, size and dimensions suitable for your application needs; surface finish preferences for aesthetics; corrosion resistance properties desired in various environments; understanding different types available on market which offers characteristics tailored towards certain applications; finally maintaining regular inspection along with periodic cleanings helps maintain their longevity. With this comprehensive guide in hand, you can confidently select the right stainless

Knowledge sharing of Stainless steel hexagonal rod bar

Unveiling the versatility of stainless steel hexagonal bar rods