Mar 13 2024

Mar 13 2024

The 316 perforated stainless steel sheet stands out. Its versatility, corrosion resistance, and strength make it a top choice for various applications. Whether you need it for architectural designs, filtration systems, or industrial equipment, this sheet offers exceptional performance and longevity. With precise round holes evenly distributed across the surface, this stainless steel sheet provides efficient airflow and aesthetic appeal. Upgrade your projects with the quality and functionality of the 316 perforated stainless steel sheet.

Corrosion Resistance

They are highly sought after for their impressive corrosion resistance. Compared to other stainless steel grades, 316 stainless steel stands out due to its excellent ability to withstand corrosion. The higher content of molybdenum in this alloy plays a crucial role in enhancing its resistance against both pitting and crevice corrosion.

The addition of molybdenum is significant as it not only boosts the corrosion resistance but also contributes to the overall strength and durability of the material. This means that when you choose a 316 perforated SS sheet, you are opting for a material that can withstand harsh environments and challenging conditions, making it ideal for various applications where corrosion is a concern.

Versatile Applications

Ideal for marine environments

Used in chemical processing equipment

Commonly found in pharmaceutical industries

Superior Strength

When using 316 perforated stainless steel sheets, you benefit from their exceptional durability and robustness. The high strength of 316 stainless steel ensures that your perforated sheets can withstand heavy loads and harsh conditions without compromising on performance.

Benefits:

Enhanced durability

Withstands heavy loads

Corrosion Resistance

The corrosion resistance properties of 316 stainless steel make it a top choice for applications exposed to moisture or harsh environments. This feature ensures that your perforated sheets remain intact and free from rust, even in demanding conditions, extending their lifespan significantly.

Benefits:

Ideal for harsh environments

Resistant to rust and corrosion

Aesthetic Appeal

In addition to its functional benefits, 316 stainless steel offers a high-quality finish that adds an aesthetic appeal to your perforated sheets. This sleek finish not only enhances the overall look but also provides a professional and polished appearance to your applications.

Benefits:

Professional appearance

Enhances aesthetics

Extending Lifespan

Corrosion resistance is vital for 316 perforated stainless steel sheets to prevent damage and prolong their lifespan. By using 316 stainless steel, which contains chromium and nickel, you ensure long-term performance and minimize maintenance costs. This type of stainless steel offers excellent protection against corrosion, making it ideal for various applications.

Prevents damage

Prolongs lifespan

Minimizes maintenance costs

Versatile Applications

When exposed to chemicals, saltwater, or high humidity, materials like 316 stainless steel are crucial due to their exceptional corrosion resistance properties. These sheets can be used in diverse environments where other materials might corrode quickly. Whether in marine settings or industrial facilities with harsh conditions, the corrosion-resistant nature of 316 stainless steel ensures durability.

Ideal for marine environments

Suitable for industrial facilities

Resistant to harsh conditions

Customization Flexibility

One significant advantage of 316 perforated SS sheets is the ability to customize the open area percentage based on your specific needs. This customization feature enables you to tailor the sheet according to your requirements, whether you need increased airflow or enhanced filtration capabilities.

Customizable open area percentage

Tailored for optimal airflow or filtration needs

Hole Shapes

When customizing 316 perforated ss sheets, you can choose from various hole shapes like round, square, or slotted. This allows you to tailor the sheet based on your specific requirements. For instance, if you need better airflow in your application, opting for a round hole shape would be ideal.

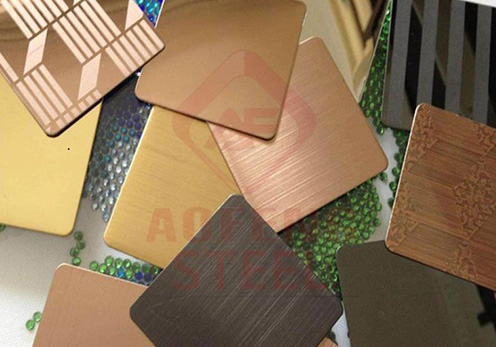

Custom Patterns and Designs Custom patterns and designs can be incorporated into the perforated sheets to serve both aesthetic and functional purposes. By customizing the design, you can enhance the visual appeal of the sheet while ensuring it meets the intended functionality. For example, if you are using the sheet as a decorative element, intricate patterns can add a unique touch.

Additional Options

In addition to hole shapes and designs, there are other customization options available for 316 perforated ss sheets. You have the flexibility to choose edge treatments that suit your application's requirements. Moreover, selecting different finishes such as polished or painted can further enhance the durability and appearance of the sheet. Lastly, varying sheet sizes ensure that you get a perfect fit for your specific needs.

Architectural and Decorative Uses

316 perforated SS sheets are perfect for creating stunning facades, intricate sunscreens, and unique interior design elements. These sheets can be customized to add a touch of elegance to buildings.

In architectural projects, perforated stainless steel sheets offer both functionality and aesthetics. They provide shade while allowing light and air to pass through, making them ideal for creating visually appealing structures like modern building facades or artistic sunscreens.

Industrial Applications

For industrial purposes in sectors such as food processing, pharmaceuticals, and chemical processing, the hygienic properties of 316 perforated SS sheets make them indispensable. These sheets are resistant to corrosion and easy to clean, ensuring a safe environment for handling sensitive materials.

Ideal for architectural designs

Enhance aesthetic appeal

Hygienic properties suitable for industries

Regular Cleaning

To maintain the appearance of 316 perforated SS sheets, clean them regularly with mild soap, warm water, and a soft cloth. Avoid abrasive cleaners that could scratch the surface.

Regular cleaning helps preserve the patterns and overall look of your sheets. By avoiding harsh chemicals, you ensure the longevity of your 316 perforated SS sheet's aesthetic appeal.

Periodic Inspections

Periodically inspect your perforated sheets for any signs of damage or corrosion spots. Promptly repair these issues to prevent further deterioration and prolong the lifespan of your sheets.

Choosing the Right Supplier for 316 SS Sheets

Proven Track Record

When selecting a supplier for 316 perforated SS sheets, ensure they have a proven track record in providing high-quality stainless steel products. Look for suppliers with a history of delivering reliable and durable materials.

A reputable supplier will have positive customer reviews, indicating their commitment to quality and customer satisfaction. By choosing a supplier with a solid reputation, you can be confident in the quality of the 316 perforated SS sheets you receive.

Customization Options

Opt for a supplier that offers customization options to tailor the 316 perforated SS sheets to your specific requirements. Whether you need specific dimensions, shapes, or patterns, having the flexibility to customize your order ensures that you get exactly what you need.

Ensure the supplier can accommodate your customization requests.

Customized 316 perforated SS sheets can meet unique project needs effectively.

In understanding the significance of 316 stainless steel perforated sheets, you've explored its exceptional corrosion resistance, diverse customization options, and wide-ranging applications across industries. By delving into the specifications and maintenance tips, you've gained insights into ensuring longevity and optimal performance. Choosing a reputable supplier for your 316 SS sheet needs is crucial for quality assurance and reliable service.

As you move forward in your quest for top-quality 316 perforated SS sheets, remember to prioritize corrosion resistance, tailor your choices to specific application requirements, and engage with trusted suppliers. Your attention to detail and commitment to quality will undoubtedly lead to successful outcomes in your projects.

What are the key properties of 316 stainless steel?

316 stainless steel is known for its excellent corrosion resistance, high strength, and durability. It is also resistant to pitting and crevice corrosion in chloride environments.

How does perforation enhance the benefits of 316 stainless steel?

Perforation allows for improved ventilation, drainage, visibility, and sound absorption while maintaining the strength and integrity of 316 stainless steel.

Can 316 perforated SS sheets be customized according to specific requirements?

Yes, manufacturers offer customization options such as hole size, shape, pattern, sheet thickness, and material finish to meet individual project needs.

What are some common applications of 316 perforated SS sheets?

These sheets are widely used in industries like architecture, food processing, filtration systems, acoustic panels, security screens due to their versatility and corrosion-resistant properties.

Why is choosing the right supplier crucial when purchasing 316 SS sheets?

Selecting a reputable supplier ensures product quality compliance with industry standards like ASTM A240/A480. It guarantees reliable customer service support and on-time delivery for your project's success.