Product introduction

| Item | Aluminum sheet | |

| Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

| Material | 1050,1060,2A14,3003,3103,4032,5454,5754,5056,5082,5086,6061,6060,6082,7075,7475 | |

| Size | Thickness | 0.2-200mm |

| Width | 100-2000mm | |

| Length | 2000mm,2440mm,6000mm,or as required. | |

| Quality control | Mill Test Certification is supplied with shipment,Third Part Inspection is acceptable. | |

| Surface | Bright,polished,hair line,brush,sand blast,checkered,embossed,etching,etc | |

| Trade conditions | ||

| Trade terms | Price term | Ex-Work,FOB,CNF,CFR,etc |

| Payment Term | TT,L/C,western Union,etc | |

| MOQ | 500Kg | |

| Delivery time | 1.The products in stock will delivery immediately received the payment. 2.According to the order quantity,prompt delivery. | |

| Package | Standard export package,such as wooden box or as required. | |

| Application | 1)Further making utensil. 2)Solar reflective film 3)The appearance of the building 4)Interior decorating:ceilings,walls,etc. 5)Furniture cabinets 6)Elevator decoraction 7)Signs,nameplate,bags making. 8)Decorated inside and outside the car 9)Household appliances:refrigerators,microwave ovens,audio equipment,etc. 10)The consumer electronics:mobile phones,digital cameras,MP3,U disk,etc. | |

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBM 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM | |

Chemical Composition

| Alloy | %Si | %Mg | %Mn | %Cu | %Fe | %Cr | %Zn | %Ti | %Others | %Al |

| EN AW-1050 A | 0.25Max | 0.05Max | 0.05Max | 0.05Max | 0.40Max | – | 0.07Max | 0.05Max | – | 99.5 Min |

| EN AW-1070 A | 0.20Max | 0.03Max | 0.03Max | 0.03Max | 0.25Max | – | 0.07Max | 0.03Max | – | 99.7 Min |

| EN AW-1100 | Si+Fe 0.95 Max | – | 0.05 Max | 0.05 – 0.20 | – | – | 0.10 Max | 0.05 Max | – | 99.0 Min |

| EN AW-2011 | 0.40 Max | – | – | 5.00 – 6.00 | 0.70 Max | – | 0.30 Max | – | Bi : 0.20 – 0.60Pb : 0.20 – 0.60 | Remainder |

| EN AW-2014 | 0.50 – 1.20 | 0.20 – 0.80 | 0.40 – 1.20 | 3.90 – 5.00 | 0.70 Max | 0.10 Max | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-2024 | 0.50 Max | 1.20 -1.80 | 0.30 – 0.90 | 3.80 – 4.90 | 0.50 Max | 0.10 Max | 0.25 Max | 0.15 Max | 0.15 Max | Remainder |

| EN AW-3003 | 0.60 Max | – | 1.00 – 1.50 | 0.05 – 0.20 | 0.70 Max | – | 0.10 Max | – | 0.15 Max | Remainder |

| EN AW-3103 | 0.50 Max | 0.30 Max | 0.90 – 1.50 | 0.10 Max | 0.70 Max | 0.10 Max | 0.20 Max | 0.10 Max | – | Remainder |

| EN AW-6101A | 0.30 – 0.7 | 0.40 – 0.90 | 0.03 Max | 0.05 Max | 0.40 Max | – | – | – | 0.10 Max | Remainder |

| EN AW-6005 | 0.60 – 0.90 | 0.40 – 0.60 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6351 | 0.70 – 1.30 | 0.40 – 0.80 | 0.40 – 0.80 | 0.10 Max | 0.50 Max | – | 0.20 Max | 0.20 Max | 0.15 Max | Remainder |

| EN AW-6060 | 0.30 – 0.60 | 0.35 – 0.60 | 0.10 Max | 0.10 Max | 0.10 – 0.30 | 0.05 Max | 0.15 Max | 0.10 Max | – | Remainder |

| EN AW-6061 | 0.40 – 0.80 | 0.80 – 1.20 | 0.15 Max | 0.15 – 0.40 | 0.70 Max | 0.04 – 0.35 | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-6063 | 0.20 – 0.60 | 0.45 – 0.90 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6082 | 0.70 – 1.30 | 0.60 -1.20 | 0.40 – 1.00 | 0.10 Max | 0.50 Max | 0.25 Max | 0.20 Max | 0.10 Max | – | Remainder |

Mechanical Properties

| Alloy | Temper | UTS (Mpa) | Yield Strength (Mpa) | Elongation (%) | ||

| Minimum | Maximum | Minimum | Maximum | A 50mm (Minimum) | ||

| EN AW-1050 A | F | 60 | – | 20 | – | 23 |

| O | 60 | 95 | 20 | – | 23 | |

| EN AW-1070 A | F | 60 | – | 20 | – | 23 |

| EN AW-1100 | O | 75 | 110 | – | – | 25 |

| EN AW-2011 | T4 | 275 | – | 125 | – | 12 |

| T6 | 310 | – | 230 | – | 6 | |

| EN AW-2014 | O | – | 250 | – | 135 | 10 |

| T4 | 370 | – | 230 | – | 11 | |

| T6 | 415 | – | 370 | – | 5 | |

| EN AW-2024 | O | – | 250 | – | 150 | 10 |

| T3,T3510,T3511 | 395 | – | 290 | – | 6 | |

| T8,T8510,T8511 | 455 | – | 380 | – | 4 | |

| EN AW-3003 | F | 95 | – | 35 | – | 20 |

| O | 95 | 135 | 35 | – | 20 | |

| EN AW-3103 | F | 95 | – | 35 | – | 20 |

| O | 95 | 135 | 35 | – | 20 | |

| EN AW-6101A | T6 | 200 | – | 170 | – | 8 |

| EN AW-6005 | T4 | 180 | – | 90 | – | 13 |

| T6 | 270 | – | 225 | – | 6 | |

| EN AW-6351 | O | – | 160 | – | 110 | 12 |

| T4 | 205 | – | 110 | – | 12 | |

| T6 | 290 | – | 250 | – | 6 | |

| EN AW-6060 | T4 | 120 | – | 60 | 14 | 12 |

| T5 | 160 | – | 120 | – | 6 | |

| T6 | 190 | – | 150 | – | 6 | |

| T64 | 180 | – | 120 | – | 10 | |

| T66 | 215 | – | 160 | – | 6 | |

| EN AW-6061 | O | – | 150 | – | 110 | 14 |

| T4 | 180 | – | 110 | – | 13 | |

| T6 | 260 | – | 240 | – | 6 | |

| EN AW-6063 | O | – | 130 | – | – | 16 |

| T4 | 130 | – | 65 | – | 12 | |

| T5 | 175 | – | 130 | – | 6 | |

| T6 | 215 | – | 170 | – | 6 | |

| T66 | 245 | – | 200 | – | 6 | |

| EN AW-6082 | O | – | 160 | – | 110 | 12 |

| T4 | 205 | – | 110 | – | 12 | |

| T5 | 270 | – | 230 | – | 6 | |

| T6 | 290 | – | 250 | – | 6 | |

PE Coating

High molecular polymer as monomer and addition of alkyd,is an UV-resistant coating.It can be classified matt and glossy according to coating gloss.The compact molecule structure,makes paint surface luster and smooth ,which assure good printing on the panel surface.With an warranty of 8-10 years for weather resistance,it is specially applied for internal decoration and sign board.

PVDF Coating

PVDF coating mainly refers to a vinylidene fluoride homopolymer or a copolymer of vinylidene fluoride and other small amount of fluorine-containing vinyl monomer.The chemical structure is stable and firm,and the physical properties of the fluorocarbon coating make the PVDF coated aluminum coil better wear resistance,impact resistance, fading resistance, and UV resistance.

Product Series

1000 Series

1000 SeriesIndustrial Pure Aluminum(1050,1060 ,1070, 1100)

3000 Series

3000 SeriesAluminum-manganese alloys(3A21, 3003, 3103, 3004, 3005, 3105)

5000 Series

5000 SeriesAl-Mg alloys(5052, 5083, 5754, 5005, 5086,5182)

6000 Series

6000 SeriesAluminum Magnesium Silicon Alloys(6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02)

7000 Series

7000 SeriesAluminum, Zinc, Magnesium and Copper Alloys(7075, 7A04, 7A09, 7A52, 7A05)

Features

Features of the 1 series

Features of the 1 series

It belongs to a series containing the most aluminum.Contains more than 99.00% aluminum, good electrical conductivity, good corrosion resistance, good welding performance, low strength.Used in conventional industry.

Features of the 3 series

Features of the 3 series

It is mainly composed of manganese.The content is between 1.0% and 1.5%, used for industries and products with high requirements for rust prevention.Good corrosion resistance, good weldability and good plasticity.

Features of the 5 series

Features of the 5 series

It belongs to the series of commonly used alloy aluminum plate,the main element is magnesium.The main characteristics are low density,high tensile strength,high elongation,good fatigue strength,but can not be strengthened by heat treatment. It is also widely used in conventional industry.

Features of the 6 series

Features of the 6 series

Contains mainly magnesium and silicon,suitable for corrosion resistance,oxidation demanding applications.

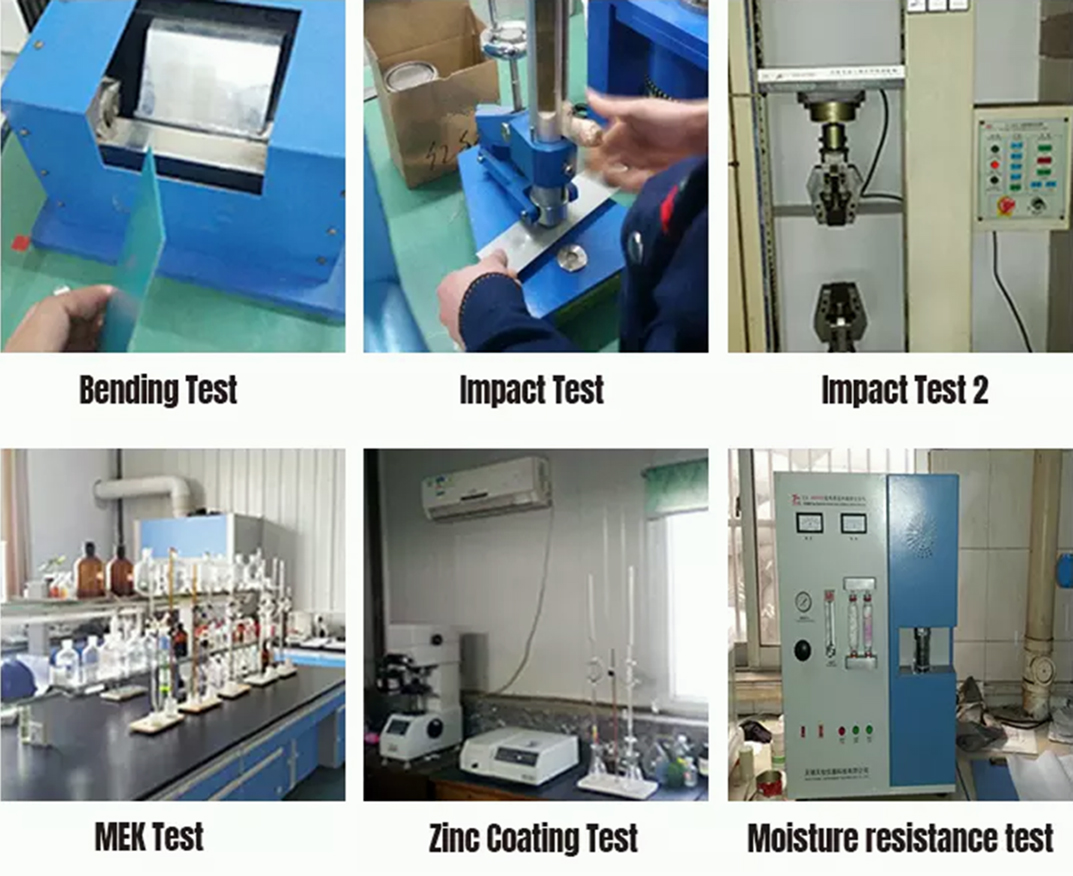

Quality Control

FAQ

Can I have a sample order for stainless steel sheet plate products?

Can I have a sample order for stainless steel sheet plate products?

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

What about the lead time?

What about the lead time?

Sample needs 3-5 days;

Sample needs 3-5 days;

Do you have any MOQ limit for stainless steel sheet plate products order?

Do you have any MOQ limit for stainless steel sheet plate products order?

Low MOQ, 1pcs for sample checking is available

Low MOQ, 1pcs for sample checking is available

How do you ship the goods and how long does it take to arrive?

How do you ship the goods and how long does it take to arrive?

We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional. For mass products, ship freight is prefered

We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional. For mass products, ship freight is prefered

Is it OK to print my logo on products?

Is it OK to print my logo on products?

Yes.

Yes.

How to ensure the quality?

How to ensure the quality?

Mill Test Certificate is supplied with shipment. If needed, a Third Party Inspection is acceptable or SGS

Mill Test Certificate is supplied with shipment. If needed, a Third Party Inspection is acceptable or SGS

Logistics

Company information

Shandong AoFeng metal material Co., ltd distribution of wholesale stainless steel plate, stainless steel pipe, stainless steel coil, stainless steel bar, stainless steel products best-selling consumer market, enjoys a high status among consumers, the company with several retailers and agents established a long-term, stable relations of cooperation.